Quality Process

HEEP&P, Germany - Pioneers of thermoQuench® Technology

HEEP&P (Hunman Engineering for Environmental Products & Production) is renowned worldwide for its cutting edge technology and sensitivity to contemporary environmental issues. It has now introduced its proprietary ThermoQuench® Technology for the first time in india.

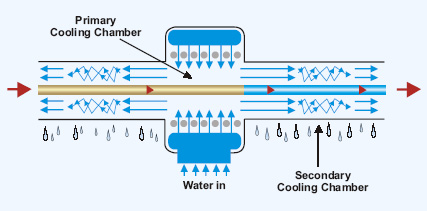

The ThermoQuench® technology process

Large quantities of low pressure water impact the hot bar in the primary cooling chamber with a very high kinetic energy. This high kinetic energy disrupts the steam jacket formation and allows for fully wetted cooling to occur immediately, bypassing the inefficient film boiling present in other designs. Inside the nozzle, precisely positioned secondary cooling chambers reintroduce turbulence, which again prevents vapour blanket (steam) formation for continued intense cooling.

The patented quenching nozzles have an extremely high heat transfer coefficient achieved by an engineered combination of laminar and turbulent flow within the nozzle.

Advantages

Achieve maximum cooling within a minimum working area

Precise control of actual heat transfer

Low system water pressure requirements

Minimum filtration required (no small orifices to clog)

Concentric cooling of the bar/wire profile

Uniform cooling along entire strand length

Smooth travel through the quenching nozzle

No bar/wire movement resulting from steam 'dancing' on bar